Executives looking to cut their reliance on China as tensions with the U.S. ramp up have a new nemesis to fight: currency volatility.

Unlike most nations, the world's second-largest economy has the relatively tame yuan, with the People's Bank of China (PBOC) setting a reference rate every day. The currency's offshore and onshore rates aren't identical, but they often move in tandem.

The yuan's stability lends a level of predictability for companies doing business there, helping them to forecast their foreign exchange (FX) needs. While the coronavirus has shown the importance of flexibility in supply chains—and renewed geopolitical strains have added urgency to the issue—changing location opens up the risk of swings in cash flow and longer-term profits from effects of currencies more prone to erratic moves.

"I've heard numerous clients say that if they weren't already diversified from China then it's very much in their plans to do so," said Jonathan Pryor, head of foreign exchange at Investec Corporate Bank. "All of a sudden they will have to deal with a more volatile currency."

Benefits of the Tame Yuan

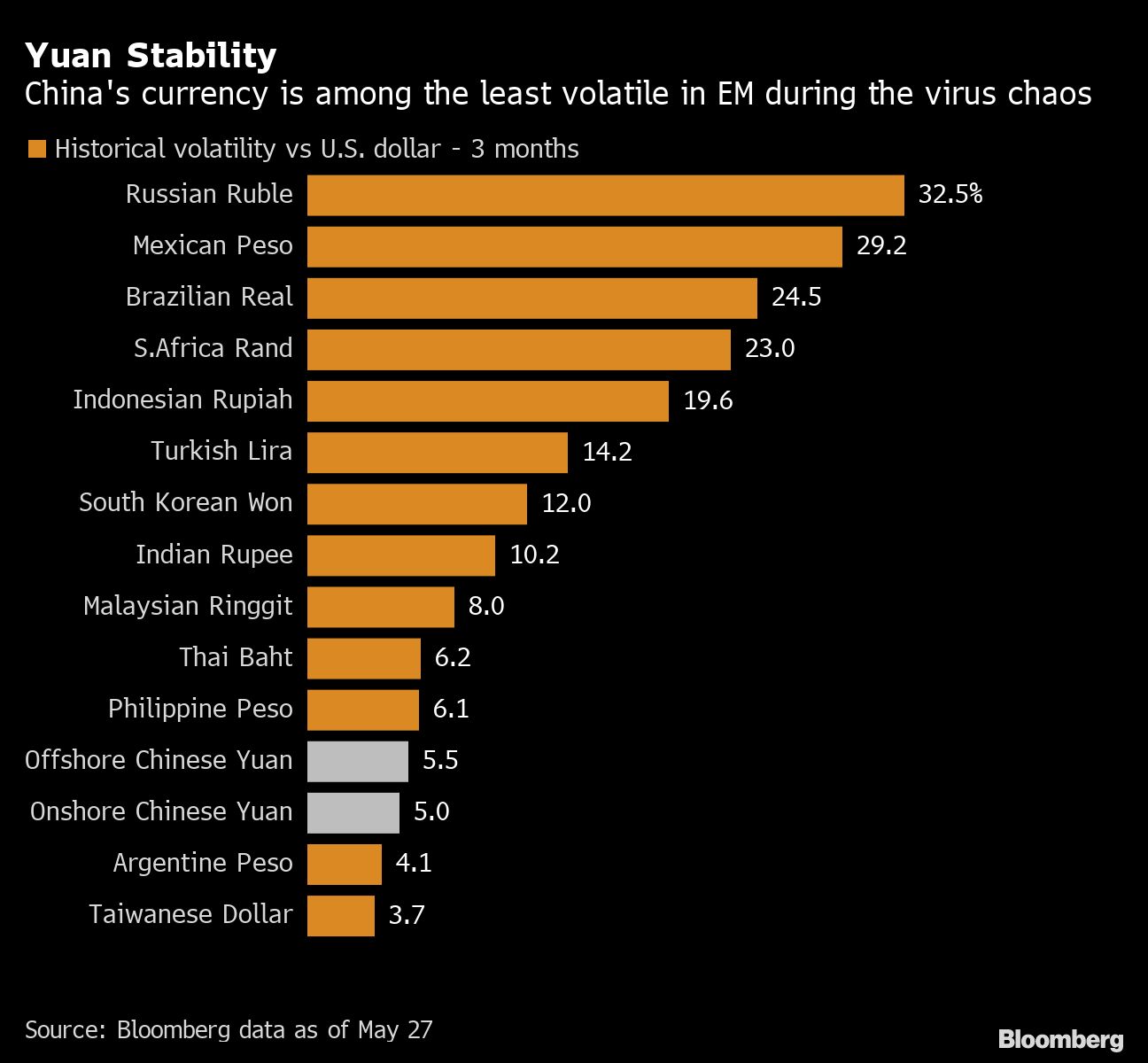

Despite China being the first to suffer the effects of the virus, and even with the offshore yuan close to a record low as of 1:30 p.m. in London on Thursday, the nation's currency is among the least volatile in emerging Asia over the past three months, according to Bloomberg data. That trend held true even as the war of words between Washington and Beijing escalated this month.

Chinese lawmakers on Thursday approved a proposal for sweeping new national security legislation in Hong Kong that could curb essential freedoms in the city. The decision came a day after the United States said it could no longer certify that Hong Kong was autonomous from China. This could mean potential restrictions on the city's special trading status with the U.S.

The tensions have seeped into foreign-exchange markets—China this week set its yuan fix at its weakest since 2008, surpassing a low in August 2019, when the U.S. announced tariffs on China. On Thursday, a stronger than expected fixing signaled that China wanted to avoid a rapid depreciation in its currency.

Even with the elevated risk concerns, the yuan's volatility was markedly lower than currencies from Indonesia and South Korea—popular alternatives for low-cost or high-tech manufacturers—which have seen the biggest FX swings in the past three months.

Wolfgang Koester, senior strategy officer for Kyriba, recently helped a Singapore-based manufacturer move its procurement from China to Malaysia and Vietnam, where the thinly traded dong hit a record low against the dollar in March. "This shift increased the complexity of their hedging programs and increased risk exposures," Koester said.

It's also more costly. Hedging $1 million against currency gyrations, through options to buy the dollar for three months, might cost about $10,000 for a China-based firm, versus almost $28,000 for those in Indonesia and about $19,000 for companies in Malaysia.

Outside of Asia, other potential bases look just as volatile from a currency perspective; the Mexican peso, Brazilian real, and South African rand are all more volatile than the Indonesian rupiah. The lira in Turkey, a common destination for textile firms moving out of China, is not far behind.

"Nobody would want lira exposure, and hedging is difficult and very costly at the best of times now in Turkey," said Viraj Patel, a currency and macro strategist at artificial intelligence firm Arkera Inc.

In spite of those costs, manufacturers based in developing markets that sell overseas and bring funds back, or just pay costs in local currencies, may still benefit. Often, emerging-market exchange rates weaken against the greenback in times of global turmoil.

Realigning supply chains became an issue long before the virus paralyzed economies. The trade war last year initiated by U.S. President Donald Trump spurred some companies to diversify their production so they're not so heavily reliant on China. In an attempt to sidestep U.S. tariffs, large firms shifted factories to other Asian nations.

Looking for a Natural Hedge

The damage the virus has caused in global trade, however, has led more companies to rethink their supply chains. Japan, whose largest trading partner is China, has earmarked $2.2 billion of its record economic stimulus package to help manufacturers shift production out of China.

In Britain, some companies had been re-jigging their strategies after the 2016 vote to leave the European Union. Now, with the virus having affected the supply chains of 82 percent of small and medium-sized U.K. manufacturers, it is only hastening the process.

Such supply gaps were a "wake-up call" for some governments on how far away some essentials were being produced, according to Rolf Ganter, head of European equities at UBS Global Wealth Management. "We really believe both companies and governments alike will look into certain supply chain issues and dependencies," he said.

A shift to bringing production closer to the end market could mean the regional proximity of such currencies would help limit some of the FX fluctuations. "It comes back to the idea of natural currency hedging," said Zurich-based Ganter. "Try to produce where you sell, because I think populism and protectionism won't go away."

—With assistance from Ven Ram and Robert Fullem.

© Touchpoint Markets, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more inforrmation visit Asset & Logo Licensing.